GV40

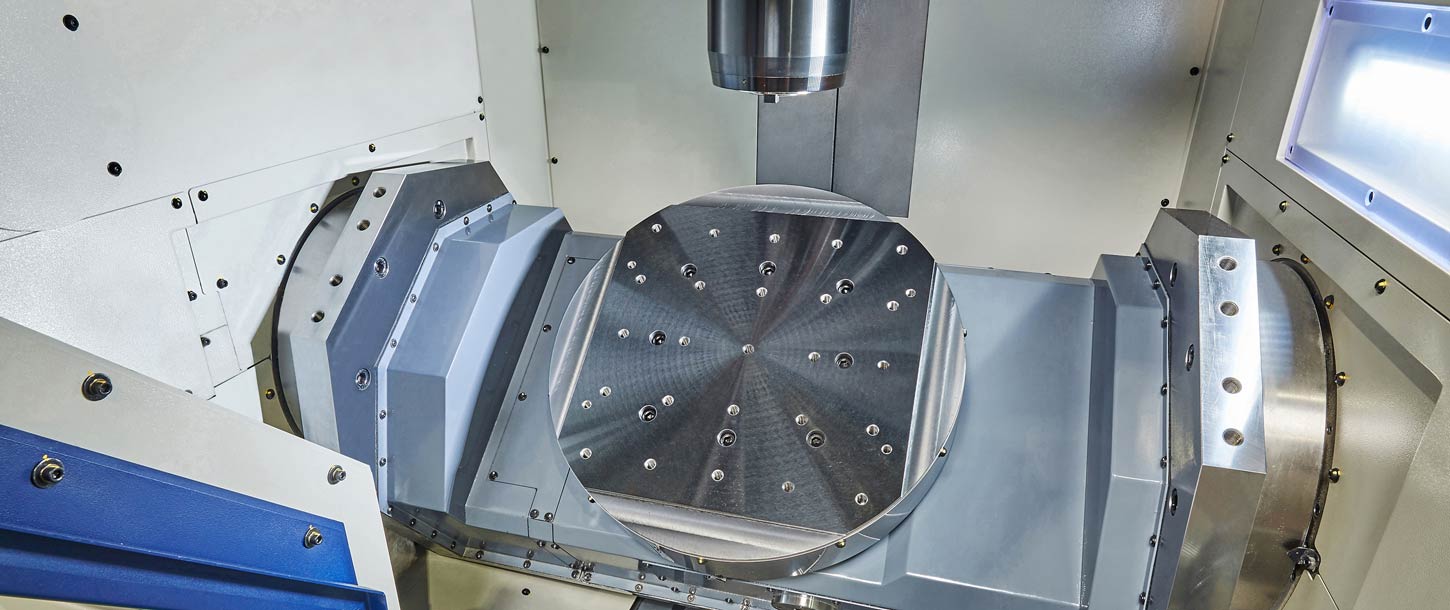

Special Machine for Glass / Ceramic Cutting

GV40

- Separation of Machining Area and Driving Area

- Various Options for Customization

Machining area and Driving area are completely separated by mounting the linear guides and ballscrews at the upper side of the machine.

Offers a variety of applications such as non-lift 2APC, dust-proofed 4/5-axis table and so on.

Easy to load and unload workpieces due to excellent accessibility.

Equipped with measures for thermal displacement specialized for glass and ceramic cutting.

Specifications

| Type of Spindle | BT40 (OP. CAT40) |

|---|---|

| Spindle speed (min-1) | 12,000 Direct drive |

| Table size (mm [inch]) | 820 × 450 [32.3 x 17.7] (with standard stroke) |

| X, Y, Z axes (mm [inch]) | 550 x 550 x 410 [21.7 x 21.7 x 16.1] (OP. 710 x 710 x 410 [28.0 x 28.0 x 16.1]) (OP. 1,000 x 710 x 510 [39.4 x 28.0 x 20.1]) (OP. 1,000 x 1,000 x 510 [39.4 x 39.4 x 20.1]) |

| Rapid feed (X/Y/Z) (mm/min. [ipm]) | 60,000 [2,362] |

| Number of tools | 20 (OP. 15/23/30/40) |

| NC | FANUC 0i-MF Plus [OP. FANUC31i-B Plus] |

| Floor space (Excluding chip conveyor) (mm [inch]) | 2,330 × 3,685 [91.7 x 145.1] (with 4/5-axis table and standard stroke) |

*Inch expression is approximate.

[OP.] ... Option